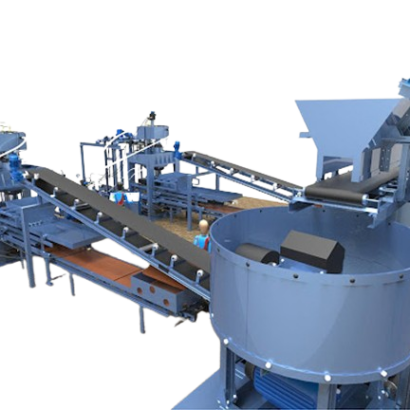

Fully automatic fly ash brick machine. 1200 bricks per hour capacity. Model AT 1313 rotary type

Model AT-1313.

Product Description :

The Model AT-1313 is a semi automatic fly ash brick making machine with 60 ton rotatry type press. Production capacity is 1200-1400bricks per hour. This machine is designed to meet the medium production demands of small construction projects, while also ensuring consistent quality and durability in the bricks produced.

Product Details :

(Rotary Mechanical type) (1000 – 1200 Bricks Per Hour*)

Related Works

Autoclaved Aerated Concrete (AAC) Block Machines

<h3>Autoclaved Aerated Concrete (AAC) Block Machine.</h3> <img width="564" height="564" src="https://www.flyashbrickmachine.org/wp-content/uploads/2022/06/AAC-Block-Making-Machine.jpg" alt="" srcset="https://www.flyashbrickmachine.org/wp-content/uploads/2022/06/AAC-Block-Making-Machine.jpg 564w, https://www.flyashbrickmachine.org/wp-content/uploads/2022/06/AAC-Block-Making-Machine-300x300.jpg 300w, https://www.flyashbrickmachine.org/wp-content/uploads/2022/06/AAC-Block-Making-Machine-150x150.jpg 150w, https://www.flyashbrickmachine.org/wp-content/uploads/2022/06/AAC-Block-Making-Machine-220x220.jpg 220w, https://www.flyashbrickmachine.org/wp-content/uploads/2022/06/AAC-Block-Making-Machine-410x410.jpg 410w, https://www.flyashbrickmachine.org/wp-content/uploads/2022/06/AAC-Block-Making-Machine-87x87.jpg 87w, https://www.flyashbrickmachine.org/wp-content/uploads/2022/06/AAC-Block-Making-Machine-200x200.jpg 200w" sizes="(max-width: 564px) 100vw, 564px" /> <h5>AAC Block Making Machine.</h5> <h5>Product details :</h5> <p><strong>Production Capacity </strong><strong>1000-1500 bricks per hour</strong></p><p><strong>Production Capacity 30 - 100 cubic meter Per Day</strong></p><p><strong>Automation Grade Semi-Automatic</strong></p><p><strong>Tolerance 0.5 mm</strong></p><p><strong>Autoclave Length 15 m - 20 m</strong></p><p><strong>Number of Layers 3</strong></p><p><strong>Method Autoclave Aerated</strong></p><p><strong>Automation Grade Automatic</strong></p><p><b>Power Requirement 65 HP to 120 HP</b></p><p><b>Material MS</b></p> <h2>Product Description :</h2> <p>Autoclaved Aerated Concrete (AAC) blocks are a highly effective, lightweight, and versatile building material that has become increasingly popular in the construction industry. These blocks are precast, meaning they are manufactured off-site and can be easily transported and installed in construction projects. AAC blocks are particularly well-regarded for their exceptional thermal and acoustic insulation properties, which help enhance energy efficiency and reduce sound transmission. Additionally, they are environmentally friendly, as they are made from natural, non-toxic materials and are often considered more sustainable compared to traditional building materials. AAC blocks are also known for their ease of handling and workability, making them a preferred choice for various construction applications.</p><p><strong>Manufacturing Process of AAC Blocks:</strong></p><p>The process of manufacturing AAC blocks involves a series of carefully planned and executed steps. These steps ensure that the final product meets the required standards for strength, durability, and other essential properties.</p><ol><li><strong>Raw Material Preparation</strong><br />The first step in the production of AAC blocks is the preparation of raw materials. The key ingredients used in making AAC blocks include:<ul><li><strong>Cement</strong>: Ordinary Portland Cement (OPC) is commonly used as the primary binder in the mixture, providing strength and stability to the blocks.</li><li><strong>Lime</strong>: Finely ground quicklime or hydrated lime is used in the process to promote a chemical reaction with water and other materials. This reaction is essential for the formation of the cellular structure in the blocks.</li><li><strong>Silica Sand</strong>: Fine silica sand or sometimes fly ash is used as a primary base material. The silica content helps in the formation of the calcium silicate hydrate that gives the blocks their strength.</li><li><strong>Gypsum</strong>: A small amount of gypsum is added to control the setting time of the mixture and ensure the proper curing process.</li><li><strong>Aluminum Powder</strong>: Aluminum powder is a critical component as it acts as a foaming agent. When mixed with water, it reacts with the alkaline lime to produce hydrogen gas, which creates the air bubbles that form the lightweight, porous structure of the AAC blocks.<strong> </strong><strong><strong> </strong></strong><strong><strong> </strong></strong><br /><ol start="2"><li><strong> Mixing </strong></li></ol><p><strong> </strong>At Ashtech, we specialize in manufacturing state-of-the-art machinery designed to deliver exceptional precision and reliability. Our advanced equipment ensures accurate material ratios, facilitating precise mixing with virtually no errors. This commitment to excellence translates into higher production efficiency and superior quality outputs, making us the trusted choice for your manufacturing needs. Once the raw materials are prepared, they are carefully measured and mixed in a precise ratio. Water is added to the dry mix to form a slurry, and the aluminum powder reacts with the lime to release hydrogen gas. This process creates small bubbles or air pockets in the mixture, giving the AAC blocks their signature lightweight, porous structure. The mixture is kept homogeneous to ensure consistency throughout the production process.</p><p><strong> </strong></p></li></ul></li></ol> <img src="https://www.flyashbrickmachine.org/wp-content/uploads/elementor/thumbs/Main-mixer-1-r11mdyxp0qj1dpf77zf5b1dr6wj16bi9lfqzmvvx1c.jpg" title="Main-mixer" alt="Main-mixer" loading="lazy" /> <img src="https://www.flyashbrickmachine.org/wp-content/uploads/elementor/thumbs/slurry-mixer-1-r11me0tdeelm0xcgx08eg0wodo9rlppq9p1ylft4ow.jpg" title="slurry-mixer" alt="slurry-mixer" loading="lazy" /> <p><strong>3. Pouring and Pre-curing</strong><br />After mixing, the slurry is poured into molds, where it begins to set and expand. The hydrogen gas bubbles created in the previous step cause the mixture to rise and take the shape of the mold. This process occurs in a controlled pre-curing room at ambient temperatures, and the slurry stays in the mold for several hours. During this time, the material achieves a semi-solid state, forming what is known as a “green cake.” This green cake is still fragile but has enough structure to move on to the next step.</p> <img width="300" height="225" src="https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/demolder-1-300x225.jpg" alt="" srcset="https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/demolder-1-300x225.jpg 300w, https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/demolder-1-200x150.jpg 200w, https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/demolder-1.jpg 400w" sizes="(max-width: 300px) 100vw, 300px" /> <p><strong>4.Cutting </strong></p><p>The cutting process is a vital stage in achieving precise dimensions for optimal product quality. At Ashtech, our advanced machinery is engineered to deliver exceptional accuracy, ensuring exact sizing and dimensions with every operation. Designed for ease of use, our cutting-edge equipment guarantees consistent outputs, maintaining the highest standards of precision and quality in every block produced Once the green cake has attained enough strength to hold its shape, it is removed from the mold and cut into blocks of the desired size. This cutting process is typically done using automated cutting machines or wires to ensure precision and uniformity in the dimensions of each block. The blocks are carefully measured to ensure they meet the required specifications and standards.</p> <img width="400" height="300" src="https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/vertical-1.jpg" alt="" srcset="https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/vertical-1.jpg 400w, https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/vertical-1-300x225.jpg 300w, https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/vertical-1-200x150.jpg 200w" sizes="(max-width: 400px) 100vw, 400px" /> <img src="https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/horizontal.jpg" title="" alt="" loading="lazy" /> <p><strong>5.Autoclaving</strong><br />At Ashtech, we specialize in designing and manufacturing autoclaves crafted from the highest quality materials. Our commitment to excellence ensures exceptional durability, a long operational lifespan, and optimal performance to meet the most demanding industry standards. After the blocks are cut, they undergo an autoclaving process. The blocks are placed inside a large autoclave, which is a pressurized vessel designed to cure the blocks using high-pressure steam. This process occurs at temperatures ranging from 180 to 200°C and pressures between 8 to 12 bar. The autoclave process lasts between 8 and 12 hours, and during this time, the blocks undergo a chemical transformation. The heat and pressure cause the calcium silicate components to form tobermorite, a strong mineral that gives the AAC blocks their strength and stability. The autoclaving process is essential in ensuring that the blocks have the necessary structural integrity to withstand the demands of construction.</p> <img width="400" height="300" src="https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/mold-1.jpg" alt="" srcset="https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/mold-1.jpg 400w, https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/mold-1-300x225.jpg 300w, https://www.flyashbrickmachine.org/wp-content/uploads/2024/11/mold-1-200x150.jpg 200w" sizes="(max-width: 400px) 100vw, 400px" /> <ol start="6"><li><strong>Quality Control</strong><br />After the autoclaving process is complete, the blocks are allowed to cool gradually. Once cooled, they undergo rigorous quality control inspections. The blocks are tested for a variety of properties, including their strength, density, and dimensional accuracy, to ensure that they meet the necessary industry standards. Any blocks that do not meet these criteria are discarded or recycled for further use in production.</li><li><strong> Packaging and Distribution</strong><br />Once the blocks pass quality control checks, they are ready for packaging and distribution. The finished AAC blocks are carefully stacked and packed, often wrapped in plastic to protect them from moisture during transportation and storage. They are then transported to construction sites, distributors, or storage facilities, where they will be used for building construction.</li></ol><p><strong>Summary of Benefits:</strong></p><p>AAC blocks offer several significant benefits, making them a superior choice in construction:</p><ul><li><strong>Lightweight</strong>: Because of their air-filled cellular structure, AAC blocks are much lighter than traditional concrete blocks. This makes them easier to handle and transport, reducing labor costs and increasing overall efficiency during construction. Additionally, the lightweight nature of AAC blocks reduces the structural load on buildings.</li><li><strong>Thermal Insulation</strong>: AAC blocks are excellent insulators, helping to regulate indoor temperatures and reduce the need for excessive heating or cooling. This contributes to energy savings and makes buildings more comfortable for occupants.</li><li><strong>Acoustic Insulation</strong>: The porous structure of AAC blocks also provides superior sound insulation, making them ideal for noise-sensitive areas. This quality helps reduce noise transmission between rooms and floors.</li><li><strong>Fire Resistance</strong>: AAC blocks are inherently non-combustible, providing a high degree of fire resistance. This makes them a safer option for construction, particularly in regions with fire hazards or for buildings that require additional safety measures.</li><li><strong>Environmentally Friendly</strong>: The manufacturing process of AAC blocks generates less waste and uses fewer raw materials compared to traditional concrete production methods. Additionally, AAC blocks are made from natural, non-toxic materials, making them an environmentally conscious choice for sustainable construction.</li></ul><p>AAC blocks are commonly used in a wide range of construction projects, including residential, commercial, and industrial buildings, thanks to their excellent properties. Whether you're building a home, office, or large commercial complex, AAC blocks offer a cost-effective, sustainable, and efficient building solution.</p><p>The weight of AAC blocks depends on their density. Typically, AAC blocks have a density ranging from 550 to 700 kg/m³. Using this density range, we can calculate the approximate weight of different block sizes.</p><p><strong>Here are the weights of some common block sizes, assuming a density of 600 kg/m³ for calculation purposes:</strong></p><p><strong>1. 600 x 200 x 75 mm:</strong><br /> - Volume: 0.009 m³<br /> - Weight: 0.009 m³ x 600 kg/m³ = 5.4 kg</p><p><strong>2. 600 x 200 x 100 mm:</strong><br /> - Volume: 0.012 m³<br /> - Weight: 0.012 m³ x 600 kg/m³ = 7.2 kg</p><p><strong>3. 600 x 200 x 150 mm:</strong><br /> - Volume: 0.018 m³<br /> - Weight: 0.018 m³ x 600 kg/m³ = 10.8 kg</p><p><strong>4. 600 x 200 x 200 mm:</strong><br /> - Volume: 0.024 m³<br /> - Weight: 0.024 m³ x 600 kg/m³ = 14.4 kg</p><p><strong>5. 600 x 200 x 230 mm:</strong><br /> - Volume: 0.0276 m³<br /> - Weight: 0.0276 m³ x 600 kg/m³ = 16.56 kg</p><p><strong>6. 600 x 200 x 250 mm:</strong><br /> - Volume: 0.03 m³<br /> - Weight: 0.03 m³ x 600 kg/m³ = 18 kg</p><p><strong>7. 600 x 200 x 300 mm:</strong><br /> - Volume: 0.036 m³<br /> - Weight: 0.036 m³ x 600 kg/m³ = 21.6 kg</p><p> <strong>For blocks with a size of 625 x 240 mm, the weights would be slightly higher:</strong></p><p><strong>1. 625 x 240 x 75 mm:</strong><br /> - Volume: 0.01125 m³<br /> - Weight: 0.01125 m³ x 600 kg/m³ = 6.75 kg</p><p><strong>2. 625 x 240 x 100 mm:</strong><br /> - Volume: 0.015 m³<br /> - Weight: 0.015 m³ x 600 kg/m³ = 9 kg</p><p><strong>3. 625 x 240 x 150 mm:</strong><br /> - Volume: 0.0225 m³<br /> - Weight: 0.0225 m³ x 600 kg/m³ = 13.5 kg</p><p><strong>4. 625 x 240 x 200 mm:</strong><br /> - Volume: 0.03 m³<br /> - Weight: 0.03 m³ x 600 kg/m³ = 18 kg</p><p><strong>5. 625 x 240 x 230 mm:</strong><br /> - Volume: 0.0345 m³<br /> - Weight: 0.0345 m³ x 600 kg/m³ = 20.7 kg</p><p><strong>6. 625 x 240 x 250 mm:</strong><br /> - Volume: 0.0375 m³<br /> - Weight: 0.0375 m³ x 600 kg/m³ = 22.5 kg</p><p><strong>7. 625 x 240 x 300 mm:</strong><br /> - Volume: 0.045 m³<br /> - Weight: 0.045 m³ x 600 kg/m³ = 27 kg</p><p>These calculations assume a uniform density of 600 kg/m³, which is a common density for AAC blocks. Actual weights may vary slightly based on the specific density used by the manufacturer.</p> <h5>Related Works</h5>

Fully automatic fly ash brick machine. Model AT-24

<h3>Fully automatic fly ash brick machine. 4500 bricks per hour capacity.

Model AT 24 - 800 ton 4 cylinder press machine with automatic pallet stacker system & batching plant.</h3>

<img src="https://www.flyashbrickmachine.org/wp-content/uploads/2023/03/unnamed.jpg" sizes="(max-width: 512px) 100vw, 512px" srcset="https://www.flyashbrickmachine.org/wp-content/uploads/2023/03/unnamed.jpg 512w, https://www.flyashbrickmachine.org/wp-content/uploads/2023/03/unnamed-300x225.jpg 300w" alt="" width="512" height="384" />

<h5>Model : AT 24 - 4500 Bricks / Hr Capacity.</h5>

<h4>Product Description :</h4>

The Model AT-24 is a fully automatic fly ash brick making machine with 800ton 4-cylinder press. Production capacity is 4500-5000bricks per hour. This machine is designed to meet the high production demands of large construction projects, while also ensuring consistent quality and durability in the bricks produced.

<h5>Product details :</h5>

<b>Production Capacity 4500-5000 per Hour </b>

<b>Pressing Cylinder Capacity 800 TON</b>

<b>No. of Main Press Cylinder 4 </b>

<b>Hydraulic Pump Motor 30 H.P</b>

<b>Cycle Time 18 Sec.</b>

<b>Oil Tank Capacity 1200 Litre</b>

<b>System Pressure 200 Kg/Cm2</b>

<b>Pump 120 Lpm</b>

<b>Pan Mixer Capacity 750 x 2 Kg</b>

<b>Pan Mixer Motor/Gearbox 30 HP/V </b>

<b>Hydraulic Trolley 500 Kg.</b>

<b>Wheelbarrow 250 Kg. </b>

<b>Compressive Strength 170 Kg/Cm2</b>

<h5>Related Products</h5>

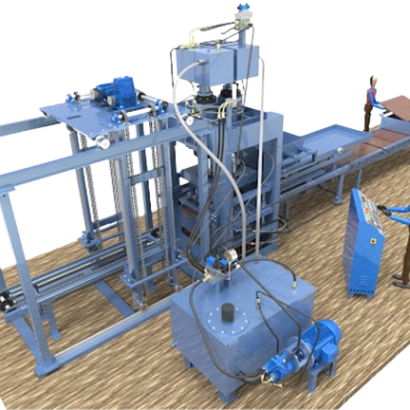

Fully automatic fly ash brick machine. Model AT-24/18

<h3>Fully automatic fly ash brick machine. 4500 bricks per hour capacity.

Model AT-24/18 - 400 ton double cylinder hydraulic press with automatic pallet stacker system.</h3>

<img src="https://www.flyashbrickmachine.org/wp-content/uploads/2023/03/400ton.jpg" sizes="(max-width: 512px) 100vw, 512px" srcset="https://www.flyashbrickmachine.org/wp-content/uploads/2023/03/400ton.jpg 512w, https://www.flyashbrickmachine.org/wp-content/uploads/2023/03/400ton-300x225.jpg 300w" alt="" width="512" height="384" />

<h5>Model : AT 24 - 4500 Bricks / Hr Capacity.</h5>

<h4>Product Description :</h4>

The Model AT-18 is a fully automatic fly ash brick making machine with 400ton Double cylinder press. Production capacity is 3600-4000bricks per hour. This machine is designed to meet the high production demands of large construction projects, while also ensuring consistent quality and durability in the bricks produced.

<h5>Product details :</h5>

<b>Production Capacity 4500-5000 per Hour </b>

<b>Pressing Cylinder Capacity 400 TON</b>

<b>No. of Main Press Cylinder 2 </b>

<b>Hydraulic Pump Motor 20 H.P</b>

<b>Cycle Time 18 Sec.</b>

<b>Oil Tank Capacity 800 Litre</b>

<b>System Pressure 200 Kg/Cm2</b>

<b>Pump 62 Lpm</b>

<b>Pan Mixer Capacity 750 x 2 Kg</b>

<b>Pan Mixer Motor/Gearbox 30 HP/V </b>

<b>Hydraulic Trolley 500 Kg.</b>

<b>Wheelbarrow 250 Kg. </b>

<b>Compressive Strength 170 Kg/Cm2</b>

<h5>Related Works</h5>